2.11.2 Fireman

Description: 1-Button Version

The Fireman audio unit improves the fire fighting operations by setting up top priority calls to the cabin audio unit in one and the same lift shaft. If any of the machine room audio units is configured as the control centre (intercom), you can join in the Fireman call.

Install the Fireman audio unit in a dedicated space that can be easily accessed by firemen.

The Fireman call has the highest priority, suspending all the other calls (refer to Function Description ).

Press the button (without detent) to set up the call. The call duration is infinite. Repress the button to stop the call.

The Fireman call setup is signalled by the Fireman audio unit LED (blue LED shining around the button).

If the control-centre (intercom) configured machine room audio unit is used, the Fireman call is signalled by a green LED flashing on the audio unit. Push (for longer than 2 s) on the audio unit keypad (green LED shining) to join in the call. Push (for longer than 2 s) on the audio unit keypad (green LED flashing) to leave the call without terminating it.

Caution

- The Fireman calls has the highest priority and suspends all the other calls except for the Fireman call set up in another shaft.

- You can join in the Fireman call from a machine room audio unit configured as the intercom.

The audio unit is fed from the CU or splitter via a two-wire bus. By disconnecting the audio unit from the bus you turn the audio unit off.

Description: Knob+Button (Push-To-Talk)

The Fireman audio unit improves the fire fighting operations by setting up top priority calls between the Fireman audio unit and the cabin and machine room audio units in one and the same lift shaft. If any of the machine room audio units is configured as the control centre (intercom), you can join in the Fireman call.

Install the Fireman audio unit in a dedicated space that can be easily accessed by firemen.

The Fireman call has the highest priority, suspending all the other calls (refer to Function Description ).

Turn the knob (0 > 1) to activate the Fireman call. The call duration is infinite. Return the knob to stop the call. Press and hold the PTT button for a required period of time to turn off the other call party's speakerphone. Release the PTT button to turn the speakerphone on again.

The Fireman call setup is signalled by the Fireman audio unit LED (blue LED shining around the button). Push the button (Push to talk) to activate the audio unit microphone and speak to the other audio units (the blue LED around the button starts flashing). While the button is pushed, no sound is transmitted from the other audio units. Release the button to allow the persons at the other audio units (cabin, machine room or machine room as intercom) to talk.

If the control-room (intercom) configured machine room audio unit is used, the Fireman call is signalled by a green LED flashing on the audio unit. Push (for longer than 2 s) on the audio unit keypad (green LED shining) to join in the call. Push (for longer than 2 s) on the audio unit keypad (green LED flashing) to leave the call without terminating it.

Caution

- The Fireman calls has the highest priority and suspends all the other calls except for the Fireman call set up in another shaft.

- The Fireman call is set up to the cabin and machine audio units in one and the same shaft.

- You can join in the Fireman call from a machine room audio unit configured as the intercom.

- The audio unit is fed from the CJ or splitter via a two-wire bus. By disconnecting the audio unit from the bus you turn the audio unit off.

Before You Start

Product Completeness Check

Please check the 2N® Lift8 Fireman package for completeness before starting installation:

- 1 2N® Lift8 Fireman

- 1 double Torx 10 / Torx 20

- Bushings (in package insert): 1x 2N® Lift8 Fireman short manual1 mounting template

- 1 big two-hole sealed bushing with nut

- 1 replaceable one-hole sealing for big bushing for thick cables

- 1 big blind with nut

- 1 small bushing with nut

- 1 big bushing packing

- 2 small bushing packings

- 4 (5 x 90) mm screws

- 4 "intelligent" (8 x 50) mm wall plugs

Electrical Installation

Use the Torx 20 spanner included in the delivery to loosen the 4 screws and remove the audio unit front cover. Find the board with electronics under the cover.

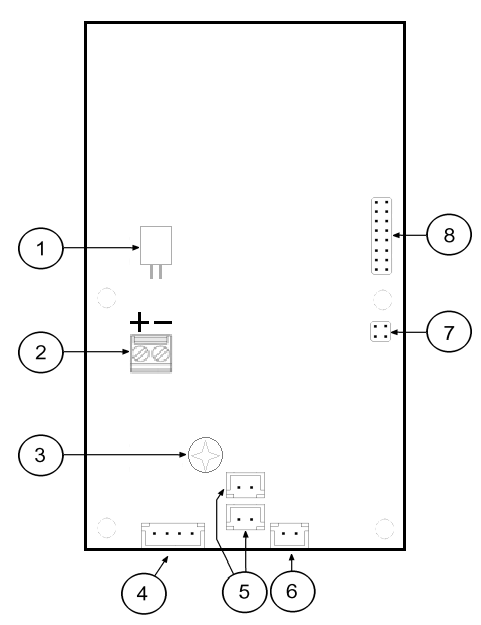

Description of Terminals, Connectors and Jumpers

Terminals, Connectors and Jumpers on Fireman Audio Unit Board

Terminals and Connectors | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1 | Speaker connector | 5 | 2 microphone connectors | ||||||

2 | Audio unit bus | 6 | Detent button (knob) connector | ||||||

3 | Volume setting (trimmer) | 7 | Configuration jumper | ||||||

4 | Button connector (Push to talk) | 8 | Servicing connector | ||||||

Bus Connection

Remove the audio unit cover and unplug terminal 2 (audio unit bus). Connect the bus and replace the terminal keeping polarity.

Warning

- The audio unit is intended for 2N® Lift8 audio unit bus connection exclusively. Do not connect it to other wires to avoid its damage or destruction.

- Keep polarity while connecting the audio unit to make the audio unit work properly.

Caution

- The audio unit is fed via a two-wire bus. By disconnecting the audio unit from the bus you turn the audio unit off.

Volume Setting

Use the trimmer on the electronics board to adjust the volume (refer to the Description of Terminals, Connectors and Jumpers above).

Caution

- Use the trimmer to set the best acoustic properties while eliminating feedback.

Mounting Completion

- Having connected all the wires, check the bushings if employed for tightness.

- Install the front panel carefully. Make sure that the wires inside the device are placed so that there is space for the front panel. Tighten the four screws again with the enclosed Torx 20 spanner, for example, to fit the panel into position on the metal chassis.

Caution

- A wrong mounting procedure may deteriorate the Fireman's water resistance and damage the electronics due to water leakage.

- 2N® Lift8 Fireman is assembled with stainless steel screws. Using different, lower-quality screws may lead to screw and surface corrosion!